Centrifugal oil separator

Centrifugal Separator - HA-60 / HA-60PLUS

Centrifugal Oil Separator for Industrial Applications

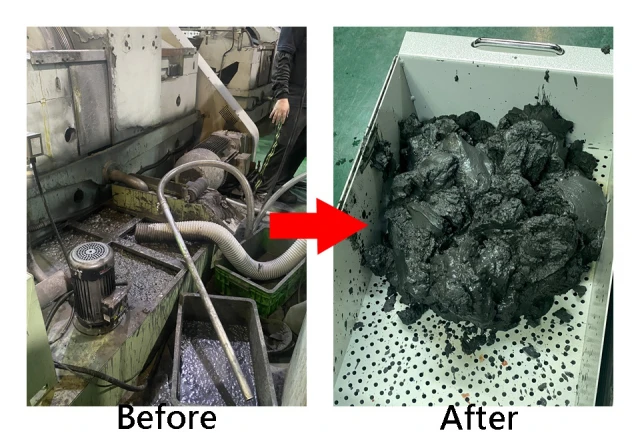

The centrifugal oil separator by King Nice is engineered for versatile industries such as lathes, milling machines, and ceramic processing. This advanced equipment efficiently handles diverse materials, including silicon, graphite, ceramics, carbon powder, and more. Designed for optimal performance, it ensures precision oil separation, water purification, and filtration in demanding industrial environments.

Two Key Functions of Centrifugal Separator Systems

- Centrifugal Water Separator — Ideal for high-frequency and CTS central water outlet systems, this separator excels in handling grinding precision cutting sewage, sludge from screw processing, and other waste streams. It provides robust solutions for water purification and sludge management, ensuring efficient operation in water-based and oily environments.

- Centrifugal Sand Separator — Perfect for separating carbon powder, glass powder, quartz powder, and fine particles from liquids, this system enhances water filtration and extends the lifespan of machinery. Whether dealing with water-soluble or oily solvents, it guarantees clean, reusable water for industrial processes.

Applications of Centrifugal Separators

The centrifugal separator is applicable across a wide range of industries, including:

Lathes, milling machines, boring grinders, special machines, ceramic processing, high frequency, CTS central water outlet system, grinding precision cutting sewage treatment, paint, sludge generated by screw processing... and other water purification and filtration systems.

Applicable materials: Silicon, graphite, ceramics, carbon powder, glass powder, aluminum powder, stainless steel powder, quartz powder, fine powder particles in liquid

Applicable solvents: Water-soluble, oily

Key Features of the Centrifugal Separator Line

- Effortless Maintenance: No need to remove the upper cover; debris can be easily cleaned.

- Self-Cleaning System: Automatically cleans the inner barrel with electric operation, avoiding direct contact with dirt.

- Efficiency Boost: Saves manpower and increases chip cleaning efficiency by 70%.

- Eco-Friendly Operation: Requires no consumables, reducing environmental impact and operating costs.

- Continuous Processing: Operates without shutting down the processing machine.

- Portable and Versatile: Mobile design for easy use across different workstations.

- High Filtration Precision: Filters particulate powders and sediment with a 95% accuracy rate.

Maintaining clean cutting fluid in machine tools is essential for ensuring optimal machining accuracy. The centrifugal separator, including our centrifugal oil separator and centrifugal water separator, offers several advantages for industrial fluid management:

- Enhanced Machining Accuracy: By consistently purifying cutting fluid, machining precision is maintained, and the defective rate of finished products is significantly reduced.

- Prolonged Cutting Fluid Lifespan: Prevents cutting fluid from deteriorating, reducing the frequency of fluid replacement and saving time and labor costs.

- Maintenance-Free Design: No clogging or filter replacement is required, eliminating additional operating costs such as filter expenses.

- Reduced Downtime and Operating Costs: Minimize machinery downtime by ensuring continuous filtration and separation, enhancing productivity and cost efficiency.

How the Centrifugal Separator Works

The operation of the centrifugal oil separator and centrifugal water separator is based on a high-speed motor driving a rotary pot to generate strong centrifugal force.

Separation Process: When machining fluid containing impurities is injected into the rotary pot, the centrifugal force separates materials by specific gravity. Heavier impurities stick to the wall of the rotary pot, while lighter liquids are thrown upward and discharged from the center.

This process ensures thorough removal of dirt and fine particles, leaving the cutting fluid clean and reusable. The efficient separation provided by the centrifugal separator reduces maintenance time, operational costs, and environmental waste, making it an indispensable tool for modern industrial machining.

|

Item Model

|

KN-HA60 | Unit |

|---|---|---|

| Effiency Capacity | 60~100 | L/h |

| A | 900 | - |

| B | 520 | - |

| C | 1625 | - |

| D | 720 | - |

| E | 985 | - |

| F | 1-1/4" | PT |

| G | 3" | PT |

| Pump horsepower | 2HP-4 pole AC220V3 phase | - |

| Air Pump | 0.5Mpa | min |

| Air Pump min presure | 0.67m3 | - |

| Net Weight | 240 | KG |

*Filtration precision/particle separation effect can reach 70%UP for 5um and above, and 95%UP for 10um and above (unit:mm)