Aerospace Applications: Precision Machining and Fluid Management

Cutting Oil Filtration Systems Enhance Aerospace Manufacturing | KingNice Tech

We are grateful for the support and trust from our aerospace industry customers! As one of our long-term aerospace manufacturing partners remarked: "The difference in precision and efficiency is remarkable." Last year, they faced challenges in managing fine metal particles and sludge generated during precision machining for aircraft components, which posed risks to operational stability.

How KingNice Addresses Aerospace Manufacturing Challenges

After adopting KingNice Tech's high-precision purification and filtration circulator system, they reported significant improvements. The system efficiently removed fine impurities from cutting fluids, ensuring optimal machining precision and improving efficiency. (See system advantages)

Integrated Oil-Water Separation and Sediment Filtration Technology

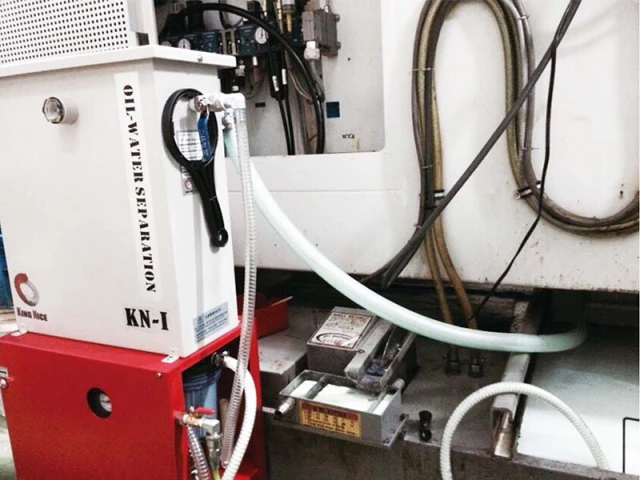

The aerospace industry has strict quality system certifications and highly complex integrated technologies, serving as a benchmark for national industrial technological capabilities worldwide. To address the challenges of cutting fluid management, KingNice Tech provides specialized oil-water separators for CNC machining centers. These systems separate oil and water in cutting fluids, enabling their reuse. This not only increases cutting fluid utilization but also effectively solves processing difficulties. (View full series)

Additionally, KingNice Tech's sediment machines, used in conjunction with regular chip filtration circulators, effectively remove oil residues, impurities, and metal shavings from cutting fluids during aerospace processing. This maintains the performance of cutting fluids and significantly extends their lifespan. (Explore chip recovery solutions)

Dual-Stage Filtration for Enhanced Performance

This year, the customer further upgraded their operations by implementing a dual-stage filtration setup, including a pre-tank filter. The results? Cutting fluids remained consistently pure, equipment wear was reduced, and environmental compliance was improved. (See how the solution works)

Key Advantages of KingNice Filtration Systems

- Maximizes machining precision

- Extends cutting fluid lifespan

- Supports compliance with environmental standards

- Mobile design for versatile operations

- Easy installation and integration

- Reduces waste management complexities

- Efficiently handles fine metal particles and sludge

Promoting Sustainability in Aerospace Manufacturing

KingNice Tech solutions not only enhance operational efficiency but also contribute to sustainable practices in the aerospace industry by reducing wastewater and complying with environmental regulations.

Discover how our innovative systems transform operations for aerospace manufacturers. From improved fluid management to higher machining precision, our customers continue to achieve remarkable results. Contact us