Why Machine Coolant Smells: Main Causes, Tramp Oil Problems, and Proven Fixes

When the cutting fluid in a CNC machining environment begins to emit an unpleasant odor, it’s not just a smell issue—it’s a warning sign that the entire coolant system is out of balance. If not addressed promptly, it can impact machining quality, accelerate tool wear, and even lead to production downtime.

This article explains the root causes of coolant odor, the consequences of ignoring it, and presents real customer cases showing how KingNice solutions effectively resolve these issues.

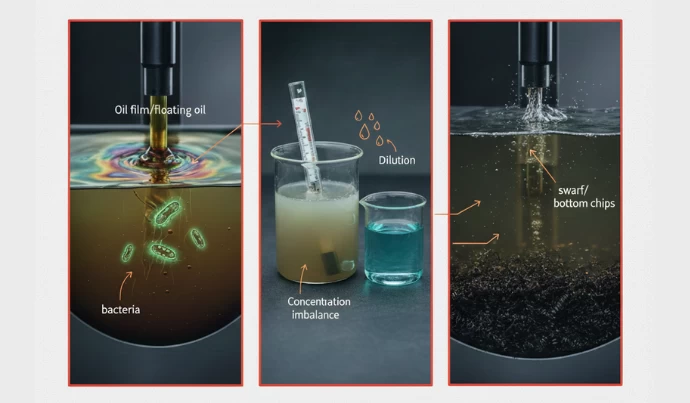

Why Does Coolant Smell? — The Three Core Causes

1. Tramp Oil Creates an Anaerobic Layer

When floating oil accumulates on the surface of cutting fluid, it forms an oil film that blocks oxygen and creates an anaerobic environment. This allows bacteria to multiply rapidly and release hydrogen sulfide, resulting in the rotten-egg odor commonly found in poorly maintained coolant systems. This is a typical sign that oil-water separation is not functioning properly.

2. Accumulated Metal Chips and Sludge Accelerate Fluid Decay

Metal fines, chips, and sludge settle at the bottom of the coolant sump and provide ideal conditions for bacterial growth. They also obstruct filtration efficiency, causing the coolant to age faster and produce strong odors.

3. Improper Coolant Concentration or Poor Fluid Management

Over-diluted coolant, incorrect chemical mixing ratios, or long intervals between maintenance will all reduce the coolant’s ability to inhibit microbial growth—making odor problems more frequent and more severe.

What Happens If You Ignore It?

- Reduced cooling and lubricating performance, causing overheating during machining.

- Shortened tool life and degraded surface roughness due to impurities and oil films.

- Lower machining accuracy and unstable production quality.

- Unpleasant working conditions and potential occupational safety concerns.

KingNice Solutions — Proven Results from Real Customers

KN-S Coolant Oil–Water Separator

KN-S Series Oil–Water Separators remove floating oil from the coolant surface and prevent anaerobic bacterial growth—stopping odor at the source.

Case: CNC turning & milling plant with 32 machines — Odor eliminated completely; coolant life extended by 3×.

KN-PLUS Heavy-Duty Oil–Water Separation System

KN-PLUS Series is designed for factories with severe floating oil issues and high contamination loads, ensuring stable coolant quality even in heavy-duty environments.

Case: Precision screw machining plant — Odor reduced by 90%, coolant successfully recycled.

KN-V Series Chip & Sludge Removal Systems

KN-V200 / KN-V300 remove bottom sludge and metal chips without interrupting production, preventing sediment buildup that causes coolant degradation and bad smells.

Case: Electroplating facility — Oil-film odor disappeared; coolant change frequency reduced by 50%.

KN-4050 / KN-A50 Ultra-Fine Coolant Filtration Systems

KN-4050 and KN-A50 remove fine particles and suspended contaminants, maintaining fluid clarity for high-precision machining or medical component manufacturing.

KingNice Product Matching Guide

Floating Oil on Coolant Surface

Recommended Equipment: KN-S, KN-PLUS

Industries: CNC machining, automotive parts

Coolant Odor Caused by Bacterial Growth

Recommended Equipment: KN-S1

Industries: Aerospace, tool & die, electronics

Metal Chip or Sludge Accumulation

Recommended Equipment: KN-V200, KN-V300

Industries: General machining, electroplating, casting

Unstable Coolant Quality

Recommended Equipment: KN-4050, KN-A50

Industries: Medical devices, high-precision components

Conclusion: Solve Odor with Technology — Not Deodorizers

Instead of relying on deodorizing chemicals or constantly replacing coolant, the best long-term solution is proper management of tramp oil, sludge removal, and maintaining coolant purity. KingNice separation and filtration systems have been proven in factories worldwide:

- Significant odor reduction

- Coolant service life extended by 2–3×

- Lower maintenance cost and improved machining stability

Looking for the right oil-water separation or filtration solution for your CNC machines? Contact the KingNice technical team today.

Updated: 2025-11-27