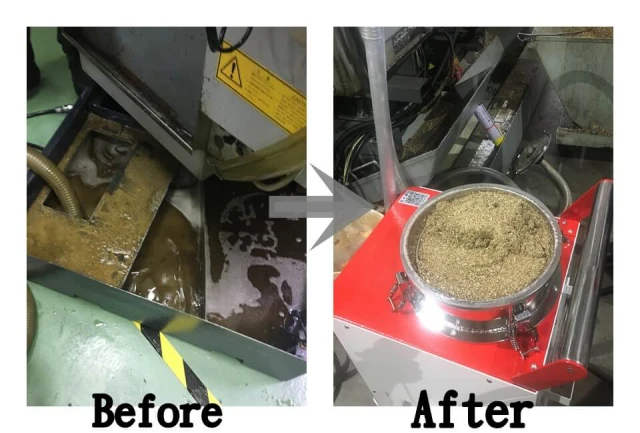

CNC Chip Vacuum and Sump Cleaner

Chip Vacuum Removal System - KN-V200

The KN-V200 Vacuum Chip Removal System uses high-powered suction to safely extract coolant, chips, swarf, and sludge from CNC machine sumps. Its heavy-duty pump provides strong suction that shortens cleaning time and supports consistent coolant quality.

Designed with sustainability in mind, the system removes bottom sludge and suspended solids from the sump—reducing industrial waste and improving operational efficiency.

The KN-V200 combines a CNC Chip Vacuum system and sump cleaner in one reliable solution—ideal for maintaining a clean, efficient, and productive CNC machining environme.

The sump cleaning machine is designed for efficient sludge removal in CNC coolant tanks

➤ Removes chips, powder, and fine sediment without interrupting operations

Effectively clears long-term buildup of iron filings, aluminum particles, and grinding debris.

Helps conserve water and coolant by recovering reusable fluids Air-powered operation improves safety and eliminates electrical hazards.

Offers filtration precision down to 1 micron—ideal for fine-particle separation.

Maintain the tank liquid capacity, and reduce temperature rise.

Reduces CNC machine failure and defect rates by maintaining coolant tank cleanliness.

Minimizes mechanical downtime and labor costs.

The CNC chip vacuum is suitable for metal cutting, aluminum machining, grinding, and engineering plastic applications.

This vacuum chip removal system enhances chip evacuation in high-volume CNC production environments

➤ Eliminates safety risks associated with electrically driven systems

➤ Enhances coolant life and overall system hygiene

-

Effectively addresses CNC tank contamination caused by iron filings, aluminum powder, fine sediment, and sludge buildup.

-

Air-powered sump cleaner offers safe and efficient operation.

-

Equipped with dehydration and sludge drying technology to accelerate cleaning operations.

-

Patented sump cleaning machine filtration system supports both water-soluble and oil-based cutting fluids.

-

Compatible with a wide range of machining equipment, including CNCs, grinders, milling machines, and lathes.

-

Quickly recovers coolant and removes sludge to reduce downtime.

-

1-micron filtration captures suspended particles and powder residues

-

The CNC chip vacuum functions as a dedicated vacuum chip removal system for high-efficiency tank cleaning in CNC operations.

Efficiency That Pays Off

85%

COST SAVINGS

15%

MACHINE AVAILABILITY

90%

TIME SAVINGS

|

Item Model

|

KN-V200 | Unit |

|---|---|---|

| Machine Size | 540X400X900 | mm |

| Filter | MAX10 | L |

| Net Weight | 45 | kg |

| Air Pump min pressure | 0.5 | Mpa |

| MAX Air | 0.6m3/m | min |

| Thickness Filter | 150~850 | um |

| Filter/SUS 304 | KFS | - |

| KFN Optional | - | |

| KFW Optional | - |

KFS Type : Thisis a durable stainless made filter, and no replacement is required.

KFN & KFW Type : This is a consumable filter, and replacement is periodically required.