Why Choose King Nice Healthy Tank Systems for Cutting Fluid Management

-

To improve the stench of the factory environment.

-

To prevent employees' health damage.

-

To avoid environmental fines.

-

Take the air pressure drive way, to avoid pubilc security problems.

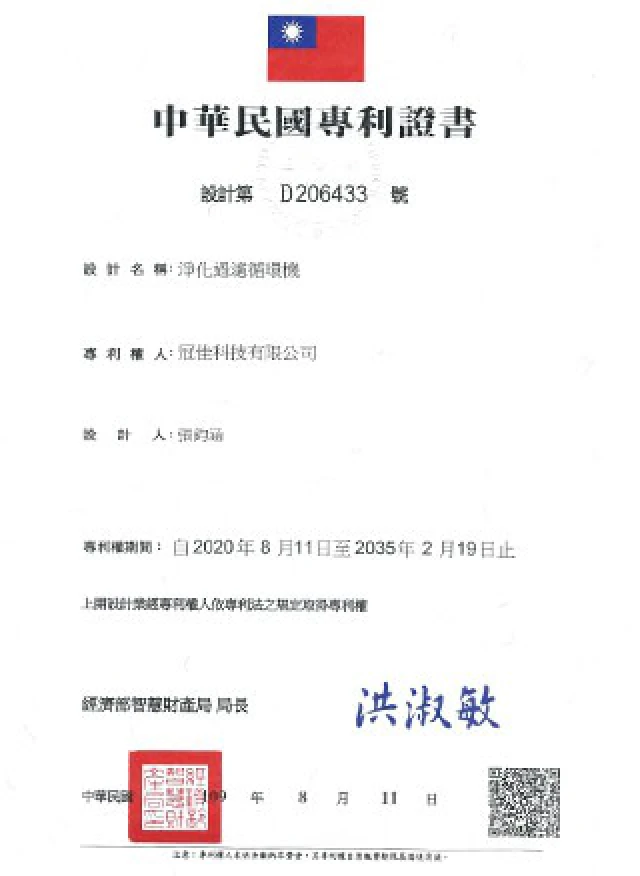

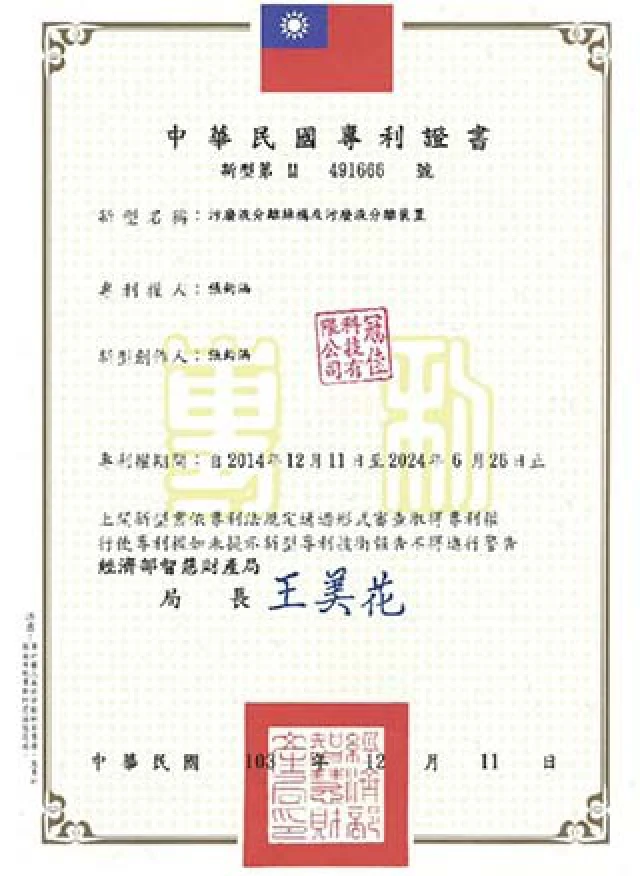

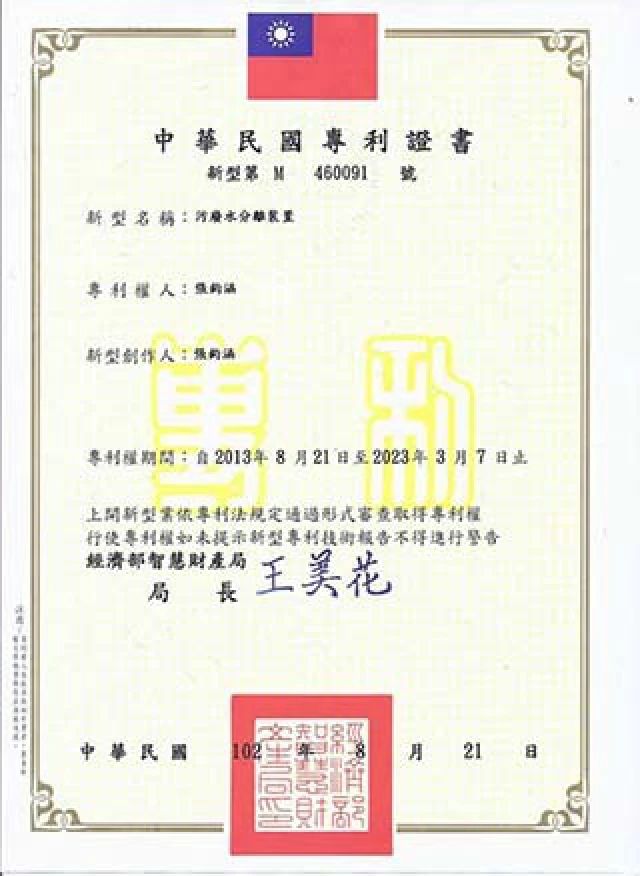

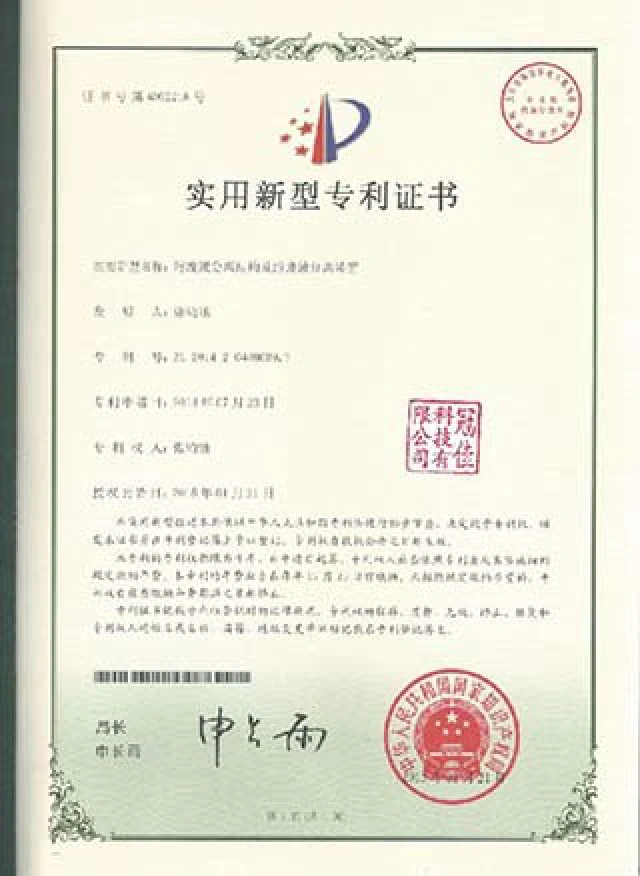

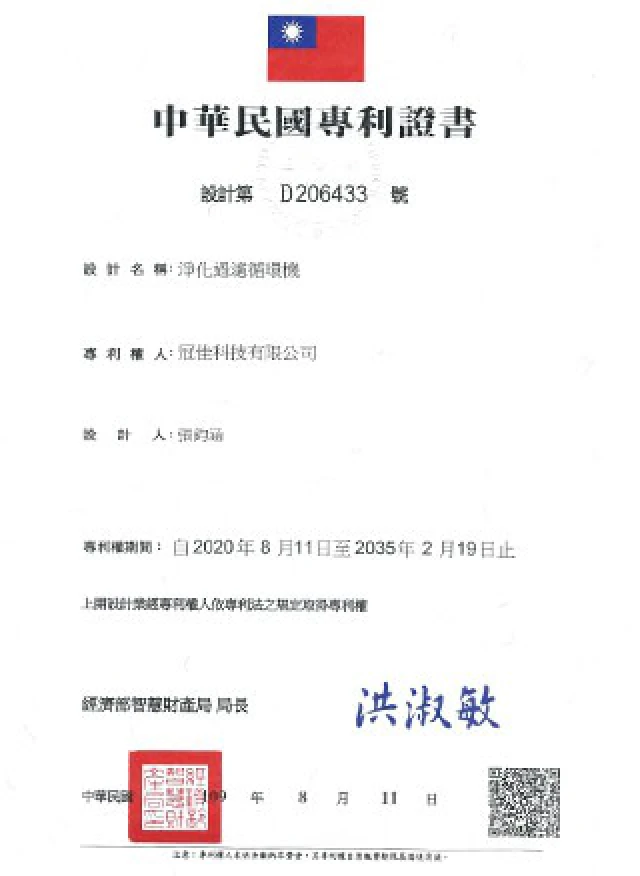

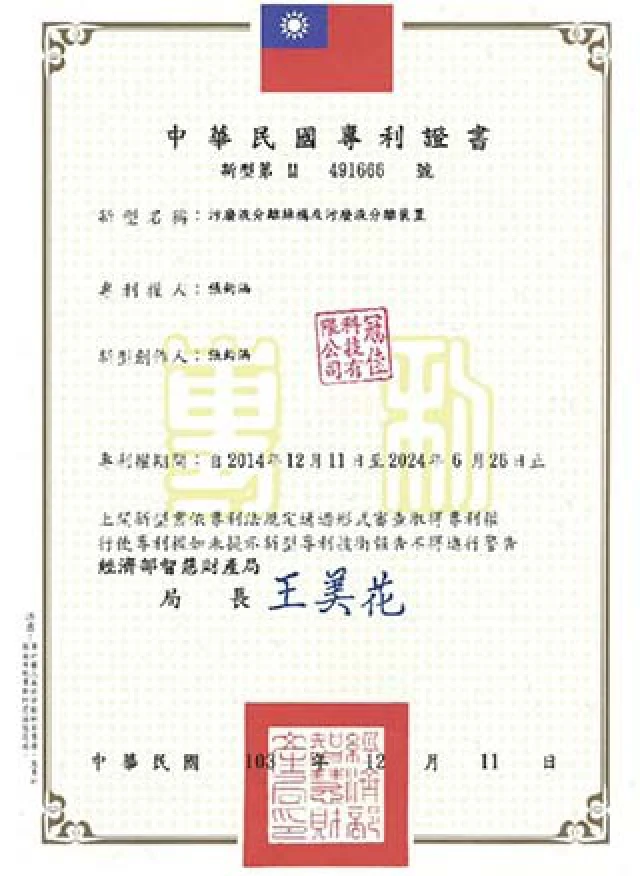

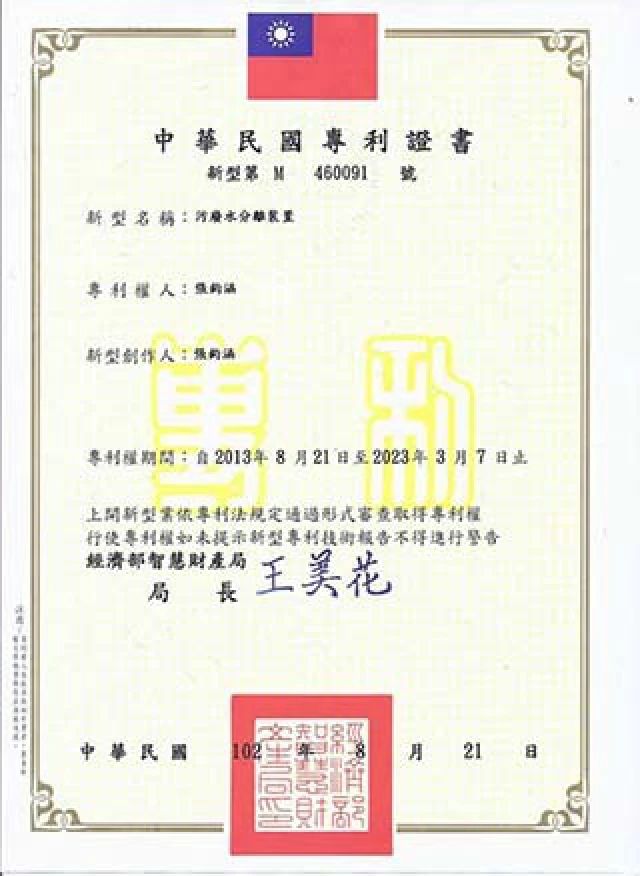

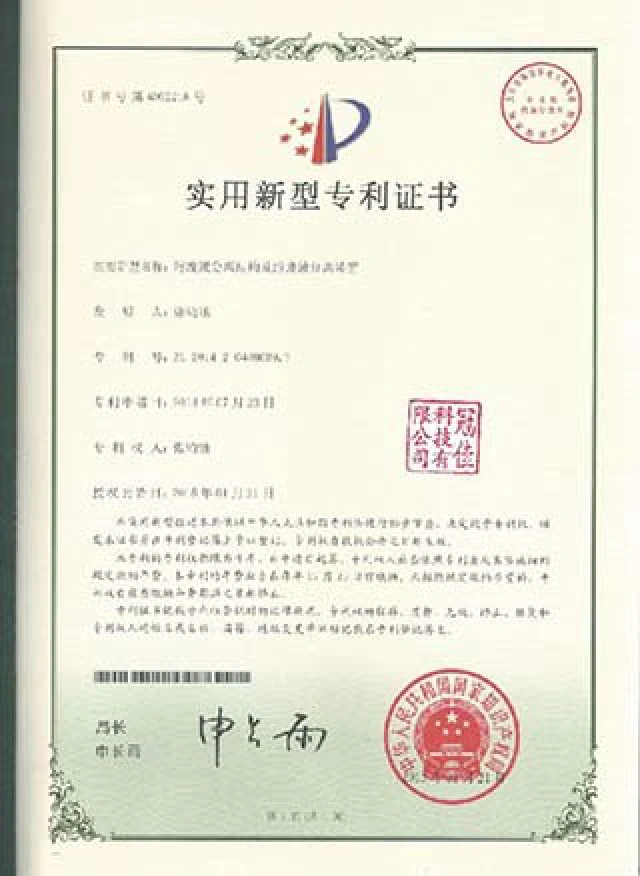

Patented technology-special dehydration drying method,can clean CNC water tank.processing liquid,sludge can also be a short time to cleat.

Reduce the cost of CNC machanical downtime and operations.

Low cost, mobile design and easy installation, which can reduce the waste of waste water and sludge and reduce the cost of supplementing cutting fluid.

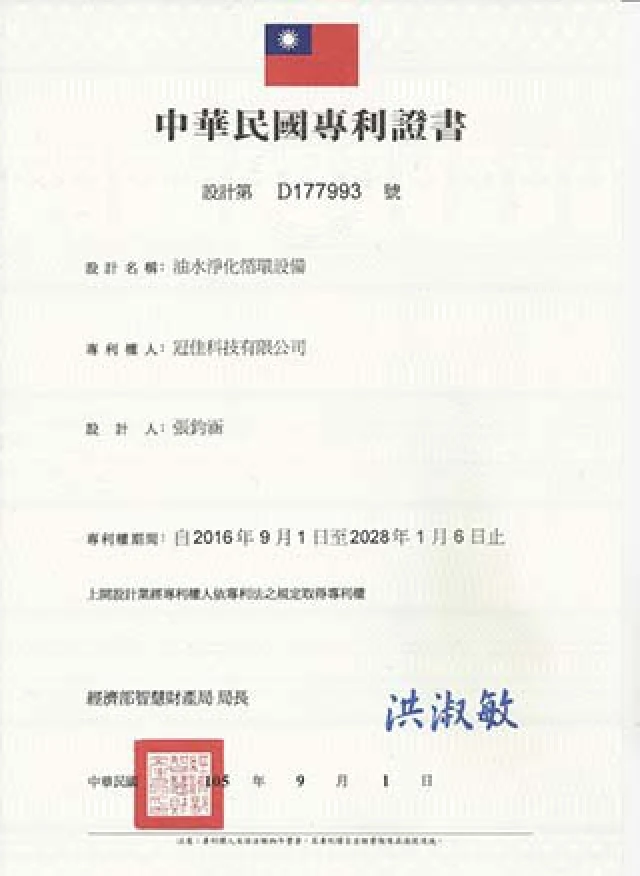

TPM media module

Patented T.P.M Description Unique patent TPM media module physically accelerates the separation of oil and water. When the oil molecules through the medium module, the small molecules condense into large molecules condense into floating oil. When suspended particles hit the media module, due to increased surface area and tilt angle, is conducive to the rapid sedimentation of suspended particles, oil and water separation procedures time is short, with a high efficiency. Physically accelerate the separation of oil and water.

TPM patent advantage

Through the patent TPM media module media filter technology and special structure design, the emulsified oil can be filtered and intercepted at one time, the waste liquid penetration rate is reduced by 50%, and the interception rate is effectively increased by more than 15%.

-

The small molecules condense into large molecules condense into floating oil by T.P.M

-

Introduction of columnar shunt can increase the impact area and number of water flow, which is beneficial to the rapid settlement of suspended particles.

-

Oil and water separation time and procedures are shortened, work efficiency is improved, and environmental engineering design can be widely applied.

Momentum and Mass

Oil Volume Fraction

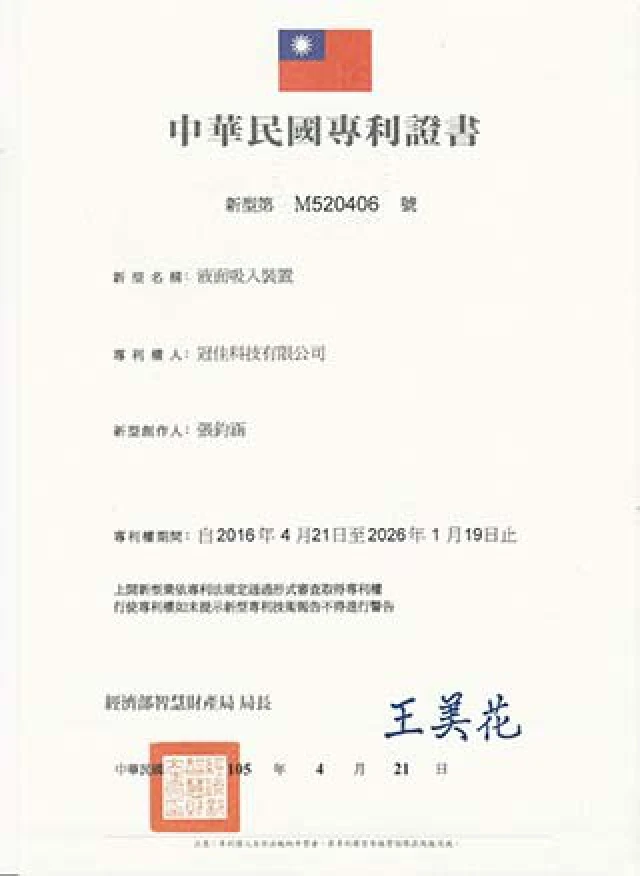

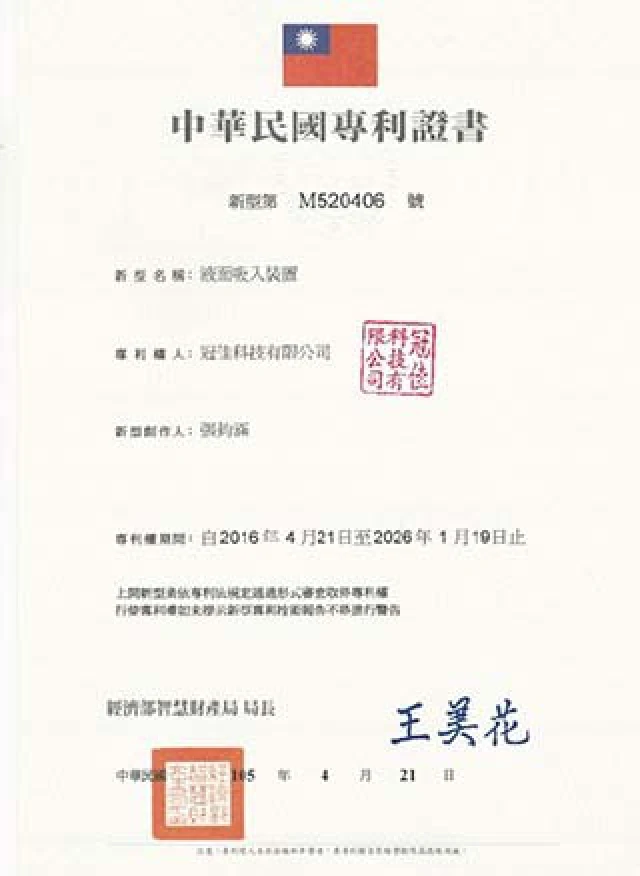

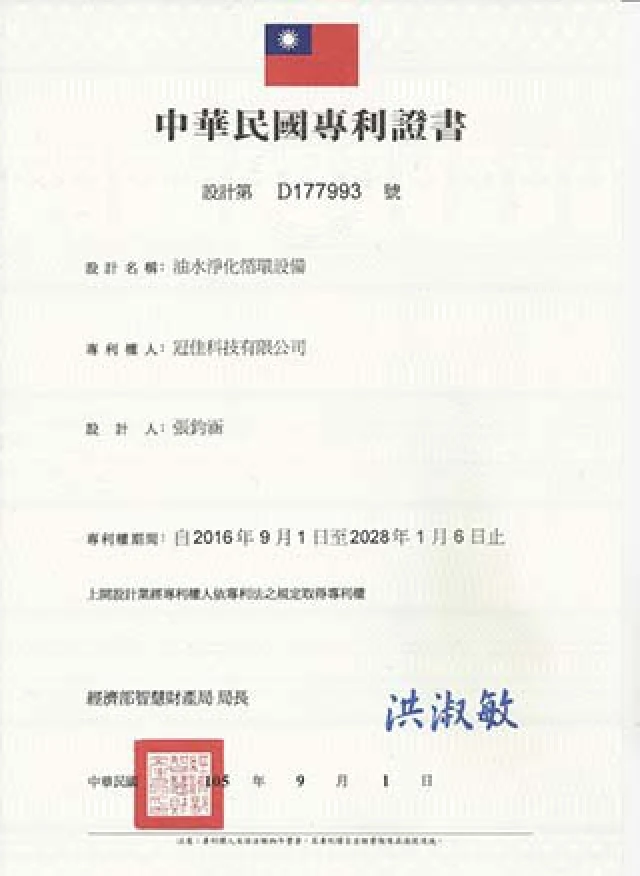

KN-SFS Floating Type Liquid Collect Device

The KN-SFS device performs high-efficiency filtration separation by drawing in surface oil from cutting fluids and directing it into a dedicated filter tank. This system separates oil, water, and solid impurities based on specific gravity differences.

Acting as both a coolant cleaner and a sump cleaner, it improves fluid quality, reduces pollution, and enhances overall recycling performance. The design also promotes turbulence and increases contact with separation surfaces, further boosting the efficiency of oil and residue removal across various manufacturing industries.